Powder Coat Division / SCOPE – Provider of Powder Coating Application for Various Industries

Welcome to Seaver Finishing Powder Coat Division. We are a family owned business since 1953. We offer value by processing parts quickly and cost-effectively through our entirely rebuilt production facility in 2017.

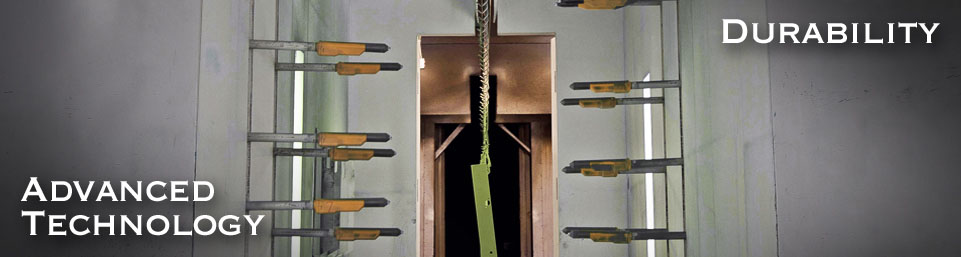

Locally designed and sourced by Belco Industries. The new system includes a 5 stage Iron Phosphate wash system with RO Rinse, ITW Gema powder booth with programmable automatics for process repeatability and hand spray options for fine tuning.

Our versatile equipment includes a large bake oven for optimal cure followed by a cooling tunnel with extended line time to cool parts for ideal packing temperature on a 1100ft conveyor with two drive units to support larger and longer parts with a part window size accommodating 14FT Horizontal, 72IN Vertical and 30IN Depth.

We excel at high volume production but are also capable of processing smaller volume projects and one off job shop orders. We offer customized schedule opportunities that include short lead times or negotiated daily turns to meet your project needs. We also partner with our E-Coat facility to offer zinc pretreated and e-coat primed parts for enhanced corrosion protection. We can negotiate trucking opportunities with quote package and offer 6 shipping docks utilizing truck to truck turn around.

Our Management teams combines 54 years of skilled powder coating experience. Our Quality Management system includes APQP activities to help dial in your customer needs. We are ISO 9001:2015 certified, CQI-12 compliant and have a robust QMS system with positive recall of production and quality records.

What is Powder Coating?

Powder Coating is a type of coating that is applied as a free flowing, dry powder. Typically applied electrostatically and cured under heat to allow it to flow and form a skin. A superior durability that is 10 times tougher than conventional paint and produces a much thicker coating without running or sagging. Powder coating production lines produce less hazardous waste than conventional liquid coatings. It also emits zero to near zero volatile organic compounds (VOC).

Powder Coat

Powder Coat

High-volume powder coat processing includes:

- ITW Gema Powder Coat System

- 16 Automatic & 2 manual guns

- Pre touch-up system for better uniformity and part coverage

- Up to 255 preset application programs to ensure accurate application to spec

- In-line six stage phosphate pretreatment system with final RO rinse

- In-line drying and cure ovens

- In-house burn-off oven for quick and efficient rack cleaning

- ISO 9001: 2015 Certified

- Window Size: Vertical 72", Horizontal 168", Depth 30"

- COATING: We have extensive experience with all coating chemistries to meet all of our customer’s needs

Request a Quote

Request a Quote